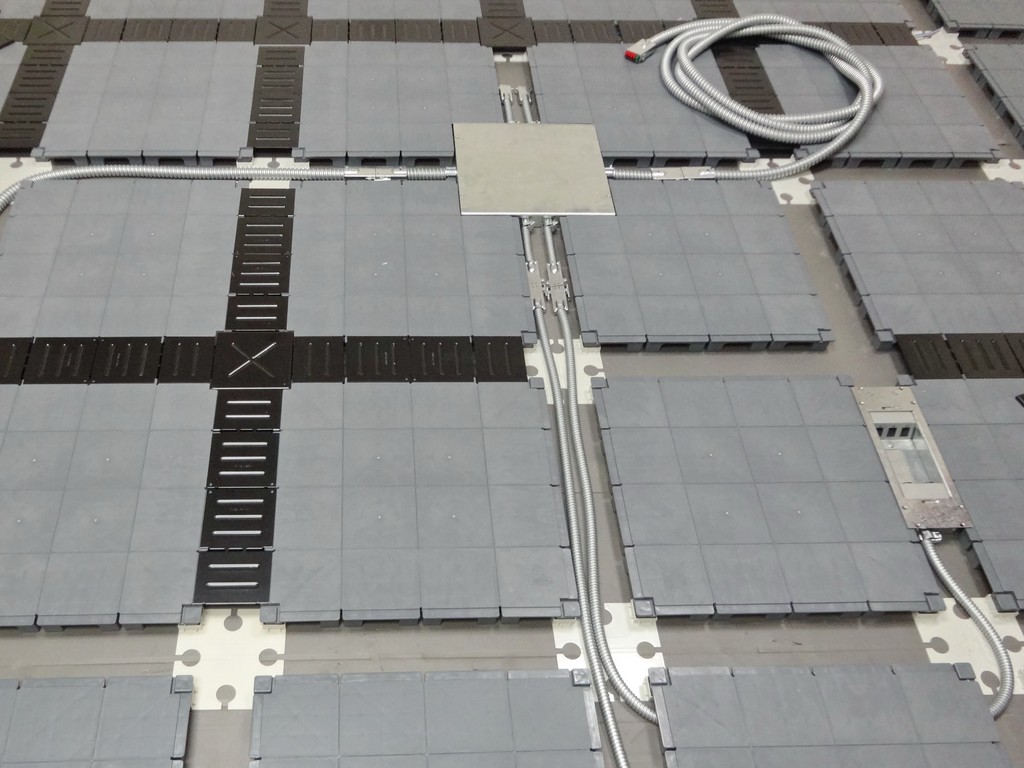

ECO Series

Netfloor ECO Series is one of the best-selling products among Netfloor product family.

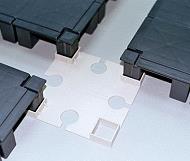

ECO series features high cable management capability at low-height, extra-durability, high changeability, easy accessibility, and more important is it’s friendly to the environment.

Since its launch in 1996, millions square meters of the ECO systems have been installed in many of the class-a office building projects, as well as in small school classrooms. To extend best sales services, the systems are distributed through Netfloor world-wide distribution network in the USA, Mexico, Brazil, Chile, UK, Spain, Benelux, Japan, HK, Taiwan, Philippines, Australia, New Zealand, Brunei,…and more to be established.

In the meantime of distribution network establishing there are emerging market opportunities to the ECO systems which you might think small possibility before. Since year 2000, besides of the offices and schools, ECO series has been growingly using in the call centers, retail stores, exhibition rooms, and even rental live/exhibition events.

ECO series features high cable management capability at low-height, extra-durability, high changeability, easy accessibility, and more important is it’s friendly to the environment.

Since its launch in 1996, millions square meters of the ECO systems have been installed in many of the class-a office building projects, as well as in small school classrooms. To extend best sales services, the systems are distributed through Netfloor world-wide distribution network in the USA, Mexico, Brazil, Chile, UK, Spain, Benelux, Japan, HK, Taiwan, Philippines, Australia, New Zealand, Brunei,…and more to be established.

In the meantime of distribution network establishing there are emerging market opportunities to the ECO systems which you might think small possibility before. Since year 2000, besides of the offices and schools, ECO series has been growingly using in the call centers, retail stores, exhibition rooms, and even rental live/exhibition events.